Problem statement

Oil production from heavy crude oil and bitumen reserves depends on enhanced thermal and chemical extraction methods like Steam Assisted Gravity Drainage (SAGD), Cyclic Steam Stimulation (CSS), and high-pressure CSS. However, these methods have several known disadvantages. SAGD and CSS consumes much higher levels of water and natural gas than used in conventional oil production and have significant production downtimes during soaking. Additionally, mixing of oil and water causes significant costs for separation. There is thus a need for cost-effective and environmentally friendly solutions for enhanced heavy oil recovery.

Technology description

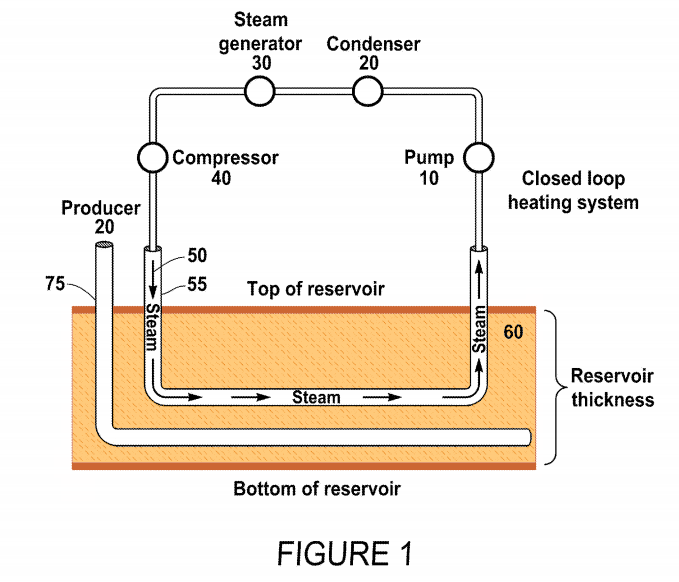

Researchers at the University of Texas at Austin provide a novel method for steam and thermal fluid assisted heavy oil recovery. The method uses a fully enclosed well-bore (Fig. 1) formed through a reservoir that can circulate fluids in a closed loop. This allows for efficient reuse of water while maintaining close proximity to the formation and reducing the viscosity of the heavy oil to a point that it becomes mobile and flows at an economic rate. Steam flow in a closed loop results in negligible water loss. Additionally, there is little concern with multi-phase flow, as the steam has minimal direct contact with the formation. Steam can be replaced with any fluid, thus making the methodology versatile.

Benefits

- Efficient re-circulation of steam

- No steam loss to the formation compared to SAGD and CSS

- Significant cost savings

- Does not require separation of oil from the heating fluid

Development

We are currently looking for partners to develop and test this system in the field. Dr. Lake is a world-famous expert in reservoir engineering, geochemistry, fluid flow in porous media, and enhanced oil recovery and is actively engaged with the industry. IP Position: Published PCT WO2018071378A1