Problem statement

Bitumen is highly viscous because of its asphaltene content (e.g., 20 wt% n-pentane insoluble), and it is often immobile at reservoir conditions. Steam injection is widely used to recover bitumen, in which the latent heat injected can effectively mobilize the bitumen near thermal fronts. However, steam injection methods, such as cyclic steam stimulation (CSS) and steam-assisted gravity drainage (SAGD), are energy-intensive, and their efficiency is highly sensitive to reservoir properties such as heterogeneous permeability, porosity, thickness, and phase saturations. It is expected that bitumen can be efficiently transported in the form of oil/water (o/w) emulsion if the emulsion is rich in bitumen and much less viscous than the original bitumen. The current technologies for bitumen recovery are based on injection of alkali (sodium carbonate), co-solvent, and synthetic surfactant for wettability alteration and interfacial tension reduction. However, sodium carbonate cannot be transported as part of the vapor in steam-injection processes (SAGD).

Technology description

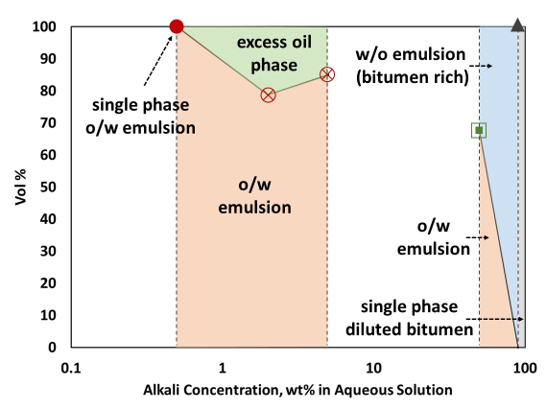

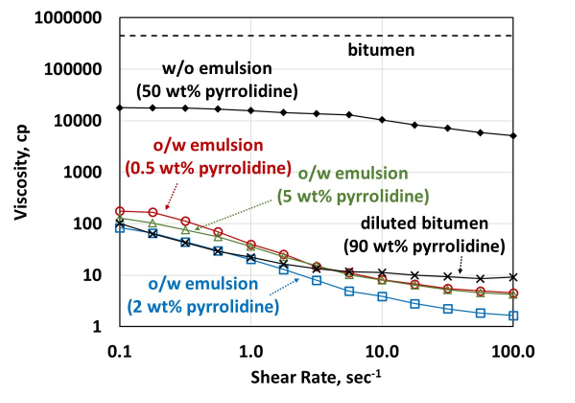

Dr. Ryosuke Okuno, a professor at The University of Texas at Austin, and his students have developed a novel technique for bitumen recovery which concentrates on bitumen-in-water emulsifications by using an organic alkali (pyrrolidine) without other surfactants or cosolvents. Pyrrolidine is superior to the other organic alkalis tested, diethylamine and triethylenetetramine, likely because its cyclic structure is more compatible with the asphaltic bitumen. The technology consists of creating o/w emulsions which are 4 to 6 orders of magnitude less viscous than bitumen. As the result, o/w emulsions created by pyrrolidine solutions can result in a large mobility increase of bitumen. The proposed new technology will work well at a wide range of reservoir temperatures. The assessment of emulsion phase behavior measurements in Fig. 1 shows stable o/w emulsion with an excess-oil phase or w/o emulsion with an excess-water phase with more favorable conditions for o/w emulsification. The results of viscosity measurements in Fig. 2 indicate that oil/water emulsions could be an effective bitumen carrier which contains a large amount of bitumen with a significantly lower viscosity than the viscosity of the original bitumen.

Key benefits and novelty

- Multiple functions of pyrrolidine as both organic alkali and cosolvent

- Works at various reservoir temperatures

- Low pyrrolidine concentration is needed

- Environmentally friendly

- Compatible with asphaltic bitumen

- Lowers the energy requirement

|  |

Fig. 1: Technology validation for emulsion phase behavior | Fig. 2: Technology validation for emulsion viscosity |