Problem statement

The efficiency of waterflooding depends significantly on the rock wettability in fractured carbonate reservoirs, which often are mixed- or oil-wet. The rock wettability is determined by the interactions among crude oil, brine, and rock minerals. The current technologies for wettability alteration in carbonate rocks, such as surfactant injection, thermal methods, and nanochemicals, are expensive, not environmentally friendly, and complicated to implement at the field scale. Amino acids are nontoxic, widely used in the food industry, and commercially available at relatively low cost.

Technology description

Ryosuke Okuno, a professor at The University of Texas at Austin, and his students have developed a novel technique displacing oil more efficiently during waterflooding in carbonate reservoirs which concentrates on application of amino acids as wettability modifier without using additional surfactants or cosolvents. The main feature that distinguishes amino acids from other wettability modifiers is the stability of glycine with formation brine at reservoir temperature. This developed technology showed promising results at the core scale to alter wettability from oil-wet to strongly water-wet conditions and it can be applied at the field scale.

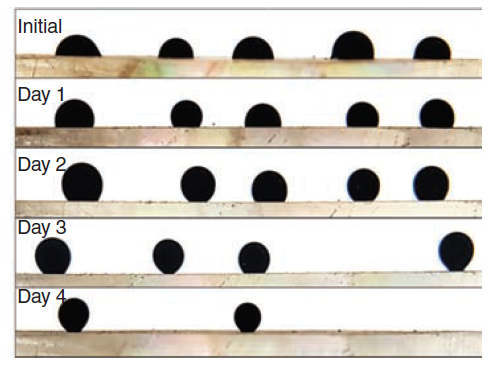

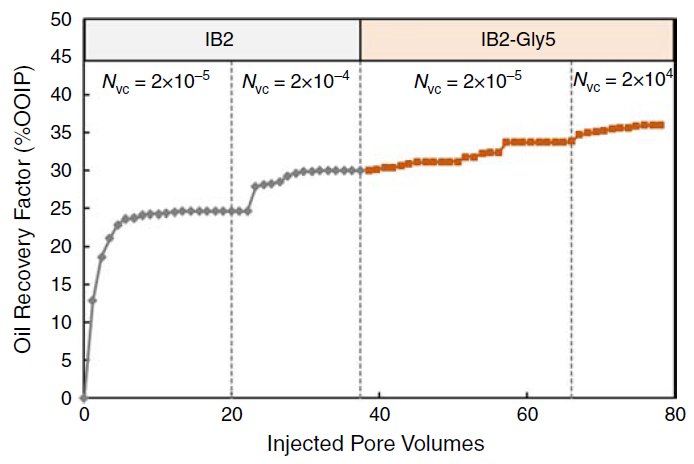

The assessment of average contact angle measurements in Fig. 1 shows that contact angle decreases from 98° to 50° with 5 wt% glycine solution at the reservoir temperature of 368°K. The positive impact of glycine on oil recovery in Fig. 2 indicates that a total incremental oil recovery of 6.1% was achieved through the wettability modification.

Key benefits and novelty

- Wettability modifying agent at different brine salinities and compositions

- Works at high reservoir temperatures

- Novel wettability alteration mechanism involving interplay between amino acid pI, solution’s pH, and rock’s pzc

- Environmentally friendly

- Commercially available at low cost

|  |

Fig. 1: Technology validation for contact angle | Fig. 2: 6.1% enhanced oil recovery using amino acid |