Background

Two of the remaining challenges in the design and construction of photovoltaics (PV) are throughput and device flexibility. Photovoltaic devices made up of crystalline layers have very limited flexibility even when using flexible substrates (such as PET) where device performance is seriously compromised. Substrates which can support flexible devices without sacrificing performance are critical. Simultaneously, PV manufacturing requires specialized equipment and it is generally not possible to manufacture the cells at the point of use.

Technology description

Researchers at The University of Texas at Austin have developed a technology which enables the manufacture of flexible solar cells. This technology uses a bacterial cellulose substrate in combination with printable nanocrystal inks. The resulting product is a device with a very high mechanical flexibility without any associated decrease in efficiency. Additionally, because the substrate is composed of organic matter, it is not only nontoxic but biodegradable. The mechanical properties of the bacterial cellulose give the added benefit that new modules can essentially be cut and paste into place. This process is amenable to on-site fabrication, which expands the developable market to areas where freight and accessibility may be prohibitive as customers can "grow" the modules close to where they wish to use them.

Results

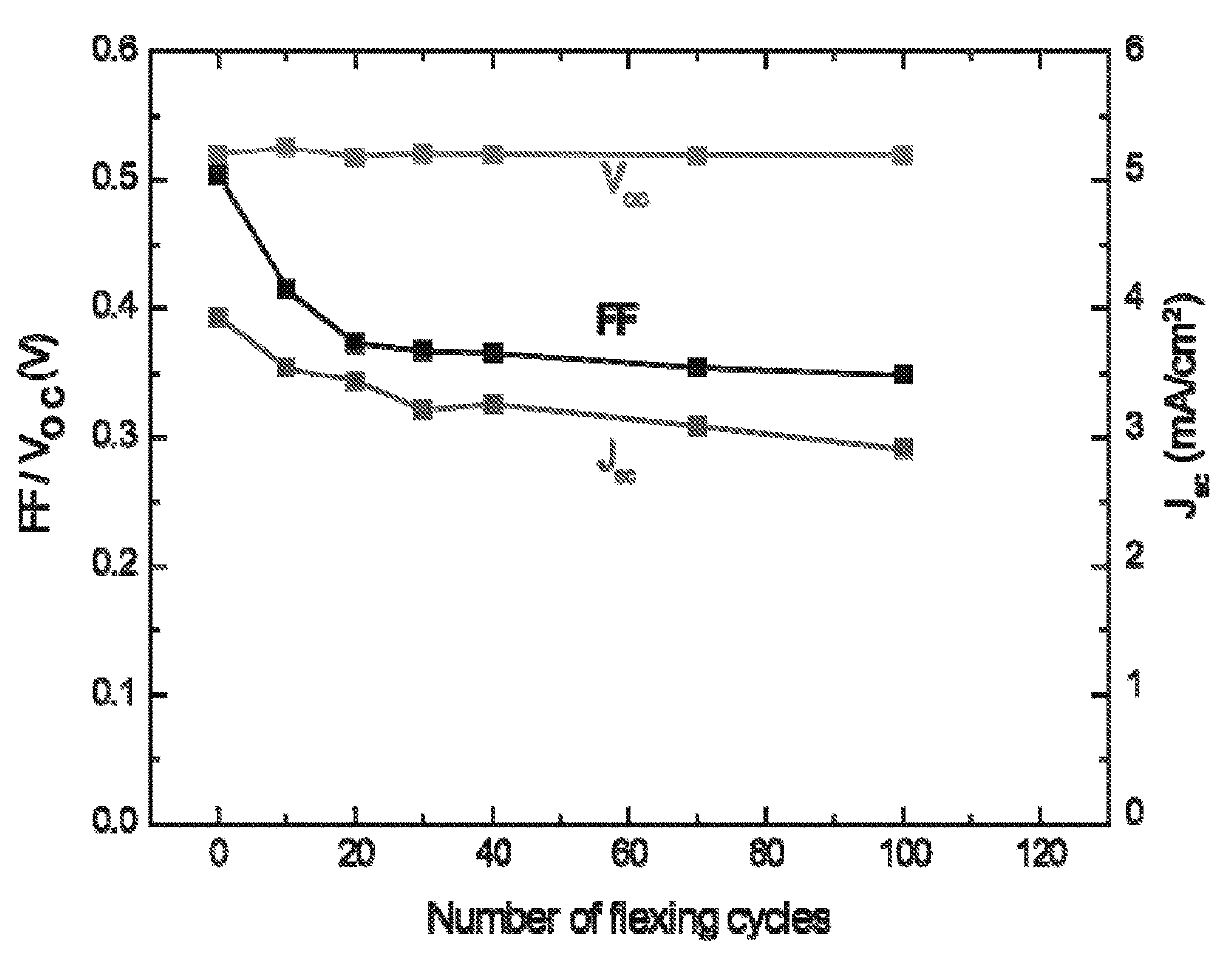

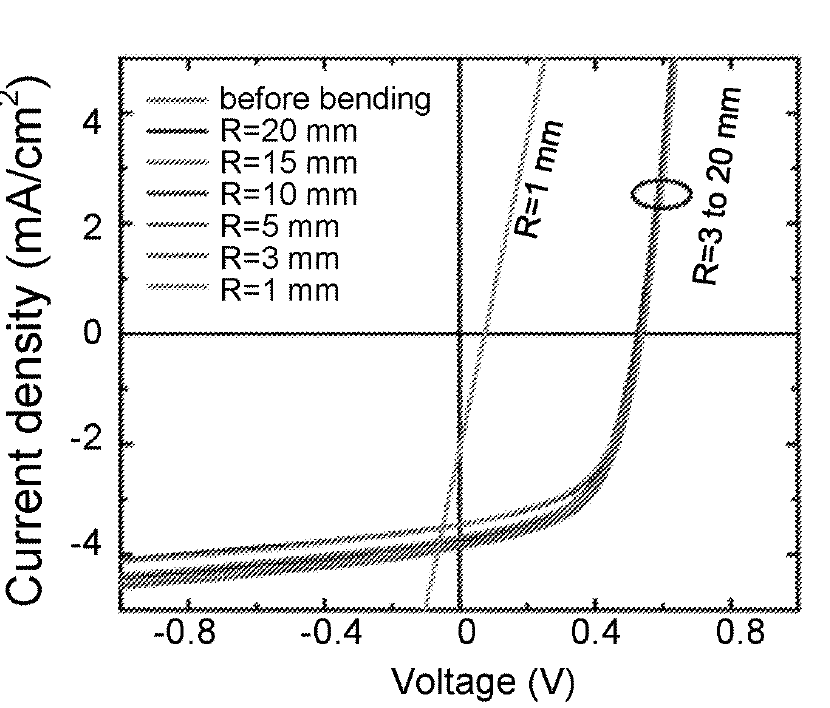

Devices printed onto the cellulose substrate have been shown to have a stable Open Circuit Voltage & Fill Factor over more than one hundred flex cycles. They have been demonstrated using multiple types of cellulosic substrates and deposition processes. Additional features may found in the public pending patent application (US 16/337,240).

|  |

Figure 1: Open circuit voltage and fill factor over bending cycles | Figure 2: Current density over a range of bending scenarios |