A versatile system for oil well injection and production

Problem statement

Recovering hydrocarbons from low permeability reservoirs is challenging due to low mobility of fluids in pore spaces. Enhanced Oil Recovery (EOR) efforts, including steam injection and chemical flooding, for such reservoirs depend on fluid injections to recover oil unavailable by conventional means. Current technologies use a dual well system with separate injection and production wells. Use of two wells is however disadvantageous due to spatial separation and inefficient placement of injection fluids in the reservoir. Additional indirect economic costs result from downtime in production from injection wells.

Technology description

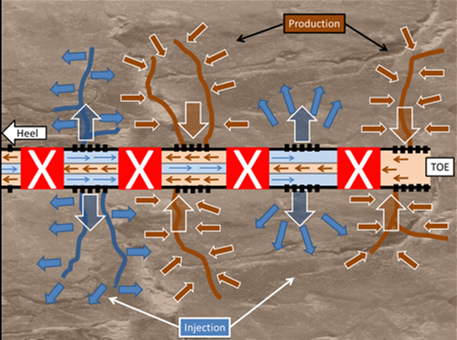

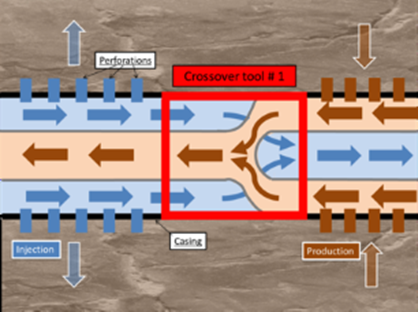

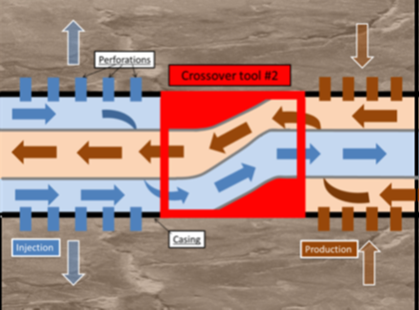

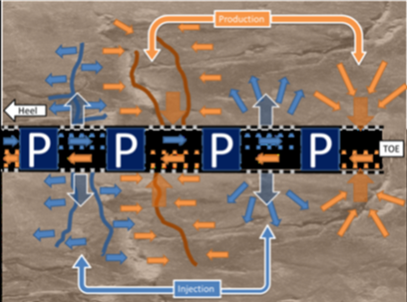

Researchers at the University of Texas at Austin have developed practical strategies to allow injection and production from the same well. By using a plurality of packers, different sections of a single horizontal or deviated well-bore can be used for both (Fig 1). The positioning of the packers acts as a cross-over tool to direct simultaneous flow from the production and injection tubes. The solutions presented are versatile and can be used independent of fracturing. Some example configurations are shown below (Fig 2a, b, c).

Fig 1: Generalized depiction of EOR using a single well

Fig 2: Some implementations of the method. Arrow indicate the direction of flow which can be reversed under particular circumstances. The separation of flow is achieved by using packers.